Attention to Detail. Great Results!

Alloys and info

I heat treat high-alloy stainless steels including, but not limited to:

Crucible CPM S35-VN®, CPM S30V®, CPM 154®, Timken-Latrobe BG 42®, Hitachi ATS 34®, Uddeholm Elmax Superclean®, Sandvik 13C26®, AEBL®, 440C, Damasteel, and Nichols stainless damascus.

I also heat treat tool steels such as O1, A2, D2, D6, 5160, L6, 52100, the 10xx series, W-series, and carbon damascus steels.

While I can attempt to heat treat your mystery steel—perhaps a file, old wagon wheel, truck spring, or other unknown source—doing so is largely guesswork. For best results, purchase quality steel from a reputable supplier. Your time and effort crafting a blade deserve reliable, predictable outcomes.

Unknown materials are guesswork when heat treating and may result in undesirable outcomes.

I employ a custom-designed heat treating furnace with full atmospheric controls and digital temperature accuracy of ±3°F at 2000°F. Heat treating and quenching cycles are tailored to the intended use of the product. Multiple quenching and tempering media are used to ensure optimal performance. Optionally, a cold tempering cycle is added to further enhance results.

My heat treating services are geared toward other knifemakers or small-scale industries needing specialty heat treating.

Additional information can be found in other sections on this page. For pricing inquiries:

Micro analysis of CPM S30V

Micro analysis of Haslinger knife and images of CRUCIBLE CPM®S30V® by SAMAC Engineering LTD.

Photograph 1:View of the knife showing where the micro was taken.

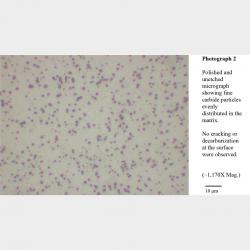

Photograph 2:Polished and unetched micrograph showing fine carbide particles evenly distributed in the matrix. No cracking or decarburization at the surface were observed. (~1,170X Mag.)

Photograph 3:Etched photomicrograph showing uniform fine microstructure throughout the specimen. (~1,170X Mag.)

Photograph 4:Higher magnification view of the etched microstructure. Chromium or vanadium carbide precipitates are shown in a matrix of tempered martensite. (~4,380X Mag.)

Heat treating considerations

Thin ground blades, off ground blades can distort during heat treating, as well have oxide/discoloration from my argon furnace. Typically the finish left from heat treating is easily removed with 220 grit.The image above is characteristic of what comes out of my furnace. Left side of the blade is after being ground with a A65 3M™ Trizact™ Gator belt.

Various reason for wrapping exist such as asymmetrical grinding - excess grinding/machining stresses, overheating during machining operations, welding or previous thermal treatments.

Stress cracks can occur for a number of reason, some are due to sharp corners, holes not chamfered, material faults.

Some deformation should be expected in virtually all blades. While the above is a rare occasion and I can straighten, I am not able to guarantee the straightness results nor replaced damaged product/material, if required to straighten.

On a microscopic level - BG42

The images shows a micro analysis that was performed by Timken Latrobe Metallurgical department on BG42® steel blade that I heat treated.

The etched photomicrograph (1000 Villelas etch) showing uniform fine microstructure and fine carbide particles evenly distributed in the matrix. The microstructure is typical of a proper heat treated BG 42 material.